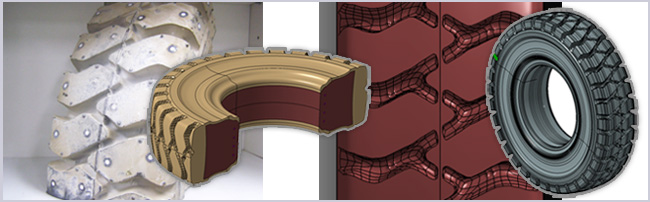

1. Finite element method

We realize that structure and flower designs are important for the quality and efficiency of tyres. Finite element is the high technology method that can simulate working condition and monitor impact of force in tyre’s construction. To ensure our tyre is suitable for heavy duty industry and all kinds of work.

Analysis step

1.1 Geometry analysis: make construction and flower model and 3D scan it to computer file. In this step we can adjust construction and flower to optimize our design with working conditions.

1.2 Material properties analysis: Formula and material properties are the most important part of tyre. We test our compound carefully by standard laboratory rubber compound in every type of function.

a.Elongation

b.Tensile strength

c.Abrasion

d.Heat build up

e.Compression set.

We combine the testing results and to create the simulation tire model.

- 1.3 Boundary condition and finite element analysis: assume work force that impacts the tyre, following the real working conditions and forklift working behavior. The program will simulate and monitor force impact between cell boundary, equivalent von mises stress, max stress at break and tresca stress.

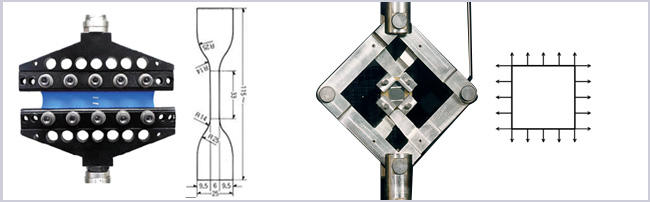

2. Endurance testing:

Usually when we test heat build up and abrasion, we use the compound for testing. But for endurance testing we can find heat build up and abrasion of tire produced in the real running conditions. We can measure heat build up at the surface and inside the construction.

The results show that our tires have a good heat build up releasing by the second layer compound and anti-abrasion in the long run.

|